Maintaining seamless operations in sectors such as food processing, pharmaceuticals, chemicals, and mining depends on effective handling of bulk materials. Commonly used pneumatic conveying systems move these goods via pipes under air or gas pressure. The airlock rotary valve is one important element guaranteeing the operation of such systems. These valves are essential to guarantee perfect pneumatic conveying by regulating the flow of materials between zones of varied pressure.

The Function of Rotary Airlock Valves in Pneumatic Conveying

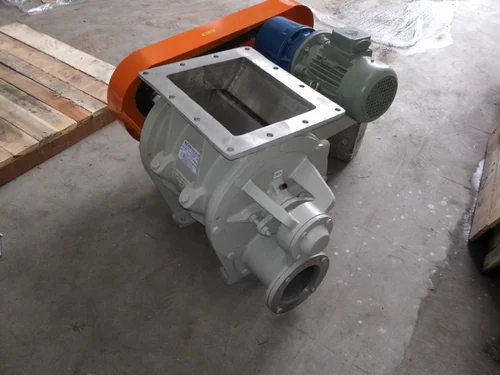

Usually in pneumatic conveying systems, rotary airlock valves act as a seal between two locations of different pressures, usually in bulk material movement from a hopper or silo into a pressured conveying line. Maintaining a pressure-tight seal, the revolving rotor of the valve with many vanes or pockets captures a certain volume of material from the inlet and moves it to the outlet. This stops air leakage, which is essential to keep system pressure stable and guarantees effective material conveyance.

Enhancing Flow Control and Efficiency

Precision and dependability of flow control are very important in pneumatic conveying. Rotary airlock valves are essential for controlling material entering the system and hence avoiding both underfeeding and overfeeding. A rotary airlock valve that is in good working order helps to preserve a consistent flow rate, therefore enhancing the general conveying process efficiency. These valves lower the danger of blockages, pressure declines, or system breakdowns causing expensive downtime by limiting variations in material supply.

Rotary airlock valves must thus be made to fit the particular qualities of the bulk material being transported in order to accomplish this. Choosing the valve design requires consideration of elements such as particle size, abrasiveness, and material stickiness. Superior building materials, including toughened steel or stainless steel, may also increase wear resistance, guaranteeing dependability over extended terms.

Maintenance and System Longevity

The lifetime and efficiency of a pneumatic conveying system depend on rotary airlock valves being routinely maintained. Particularly when handling abrasive materials, valve components like the rotor, vanes, and housing might suffer with wear and tear over time. Timeliness of replacement of worn-out components, cleaning, and routine inspections assist to minimize leaks and guarantee the system keeps running effectively.

Perfect operation of pneumatic conveying systems depends on airlock rotary valve. These valves maximize the conveying process by exact control of material flow and preservation of pressure integrity. Rotary airlock valves increase system efficiency, lower downtime, and raise general production when chosen and maintained appropriately.