High-precision current measurements require accurate and reliable measurement techniques. Thus, a current transducer and tester are needed to perform solutions for high-precision current measurements. There are several solutions used for high-precision current measurements. These solutions are discussed below.

Current shunts

A current shunt is a precision resistor with a known resistance value that is placed in series with the current path. By measuring the voltage drop across the shunt resistor, Ohm’s law can be used to calculate the current flowing through it. Current shunts can provide accurate measurements when calibrated properly.

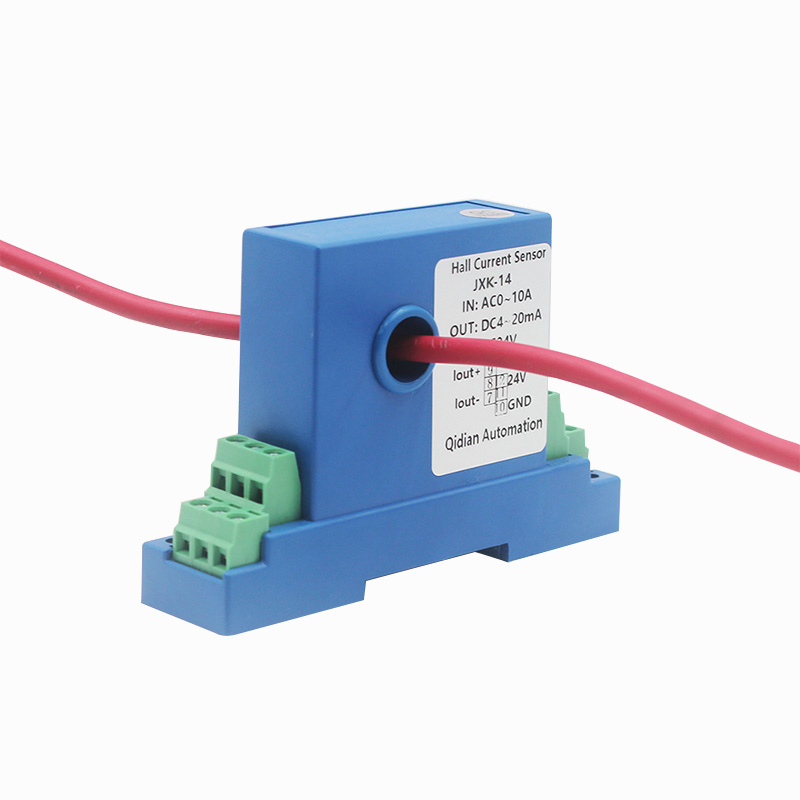

Hall effect sensors

Hall effect sensors use the principle of the Hall effect to measure current. When a current passes through a conductor placed in a magnetic field, it generates a voltage across the conductor perpendicular to both the current and magnetic field. Hall effect sensors detect this voltage and provide a measure of the current. It can offer high accuracy and galvanic isolation.

Rogowski coils

Rogowski coils are flexible current sensors that consist of a coil wound on a core. It is capable of measuring alternating currents and providing a voltage output proportional to the rate of change of current. Rogowski coils are often used in applications where high-frequency current measurements are required.

Current transformers

Current transformers (CTs) are commonly used to measure alternating currents. These are in accordance with the principle of electromagnetic induction. CTs consist of a primary winding through which the current flows and a secondary winding that provides a reduced current output proportional to the primary current. It offers galvanic isolation and can handle high currents.

Precision current measurement circuits

Dedicated integrated circuits (ICs) designed for high-precision current measurements are available in the market. These ICs often incorporate amplification, filtering, and analog-to-digital conversion capabilities to provide accurate current measurements. These can be integrated into systems for precise current monitoring.

Calibration and compensation

Regardless of the measurement technique used, calibration is crucial for achieving high-precision current measurements. Calibration involves comparing the measurement system to a known reference standard and adjusting it accordingly. Additionally, compensating for factors like temperature, linearity, and offset errors can further enhance the accuracy of current measurements.

The choice of the solution depends on factors such as the type of current (AC or DC), the magnitude of the current, the required accuracy, the frequency range, and the specific application in which the measurements are being performed. Consulting with experts in the field and considering the specific requirements will help in selecting the most appropriate solution for high-precision current measurements.

It is helpful to carefully consider the specific requirements of the measurement task and consult with experts in the field to select the most suitable solution. Proper calibration and compensation are vital to ensure accurate and precise current measurements. By employing the right techniques and equipment, high-precision current measurements can be achieved in a wide range of applications.